The chemical industry faces a complex dilemma: chemical production is expected to quadruple by 2050 to meet the ever-increasing demand. Yet, the industry needs to reduce greenhouse gas emissions by more than half to meet sustainability goals. For modern society to function, we need to find ways to sustainably produce everything — from medicines to food products, flavourings, cosmetics, plastics and even fuel.

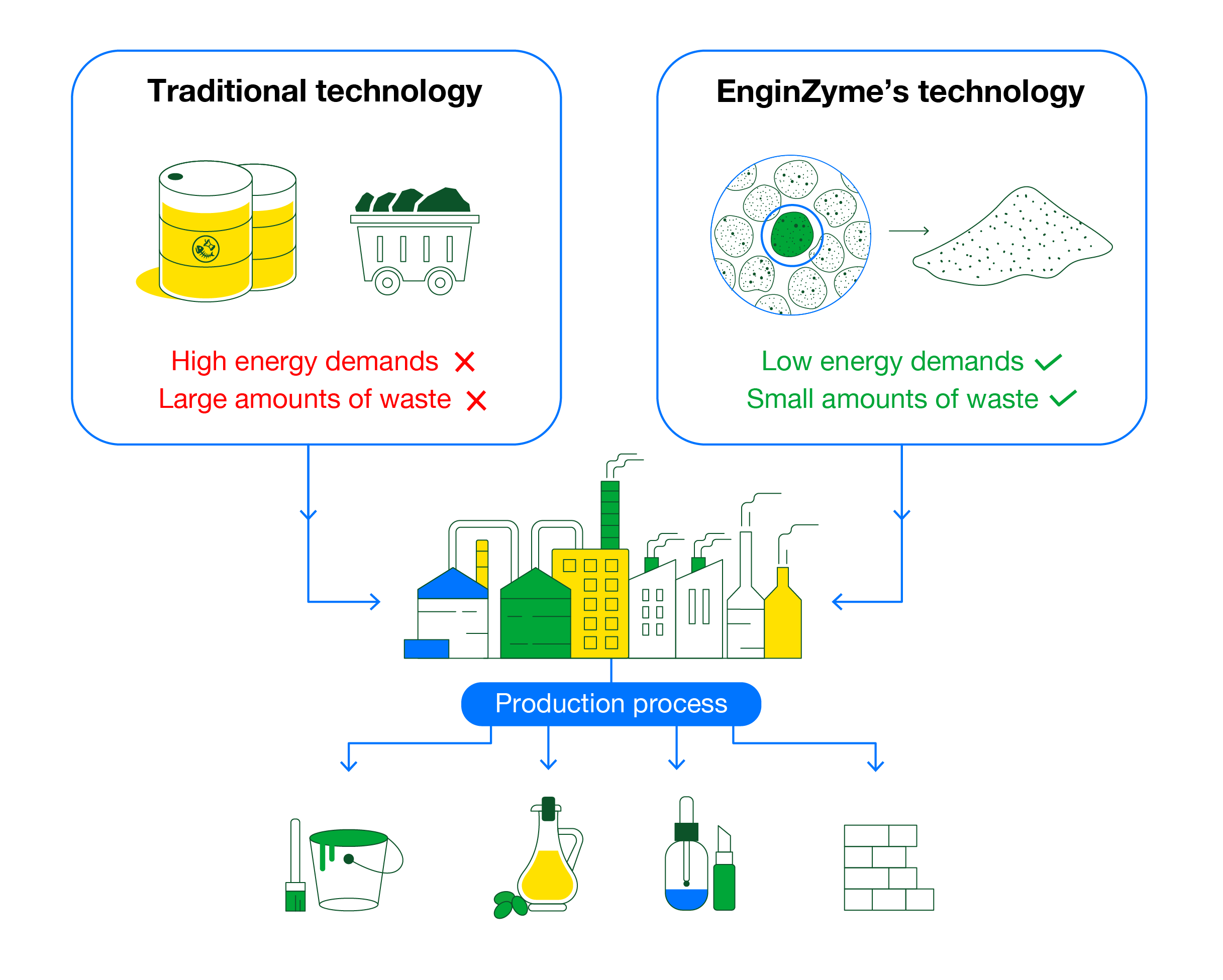

Current chemical manufacturing processes generate too much waste and use too much energy to be sustainable. Most chemical manufacturing involves petroleum feedstock and catalysis through lots of heat, pressure, and the use of metals. The heat created wastes energy, and the amount of physical waste produced from these processes is excessive, not to mention costly to dispose of.

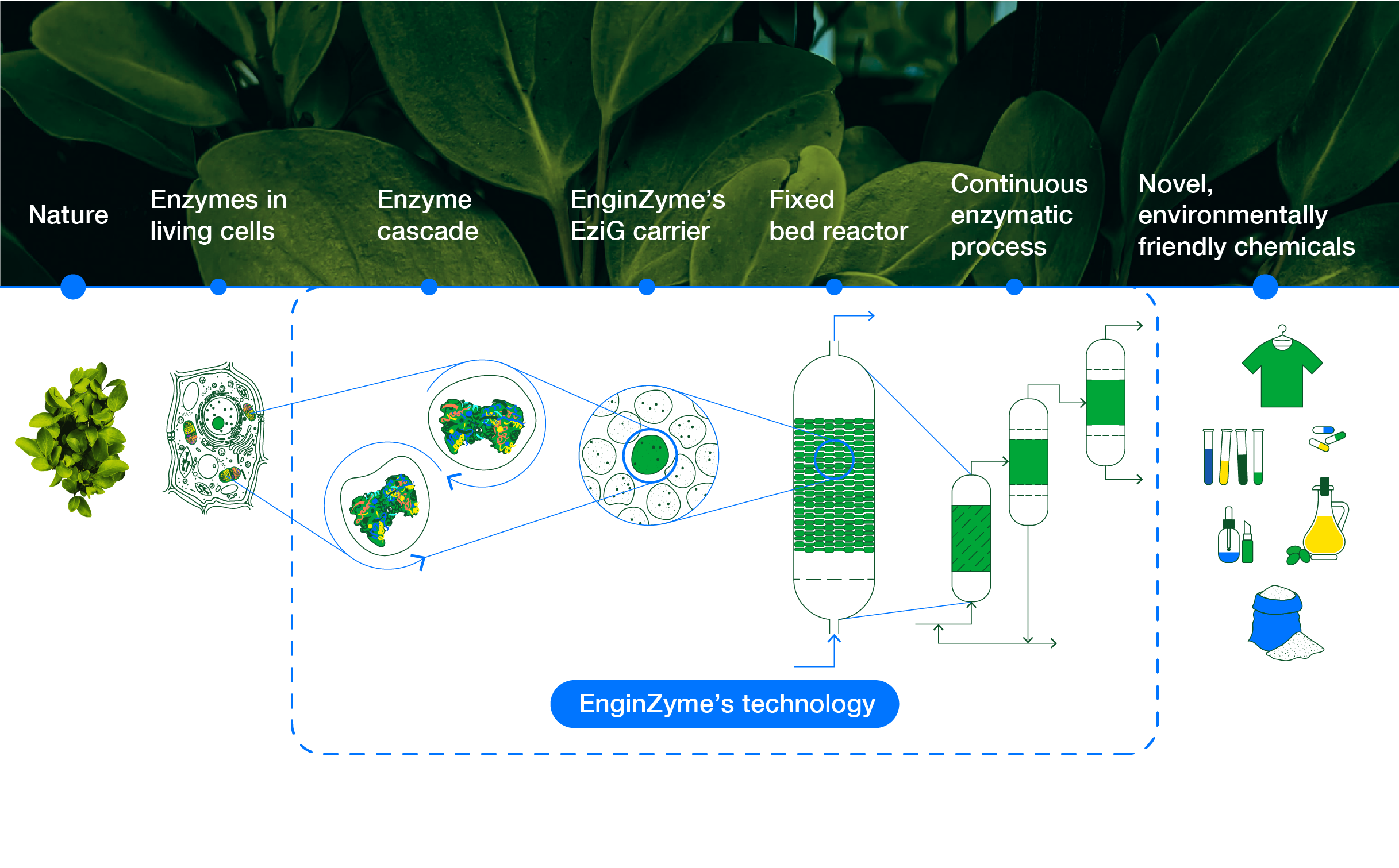

Nature is much more efficient. That’s why many green chemistry companies have biomimetic processes — they imitate what nature does. In the natural world, enzymes are the key catalysts that allow cells to create chemicals necessary for life. But using living cells for manufacturing chemicals or transforming products industrially can be a delicate, fickle process that requires a highly conditioned environment known as a bioreactor.

At EnginZyme, we create biomimetic processes, but instead of living cells, we use a patented process that allows us to use enzymes the way the traditional chemical industry uses catalysts — but under much gentler, less energy-intensive conditions.